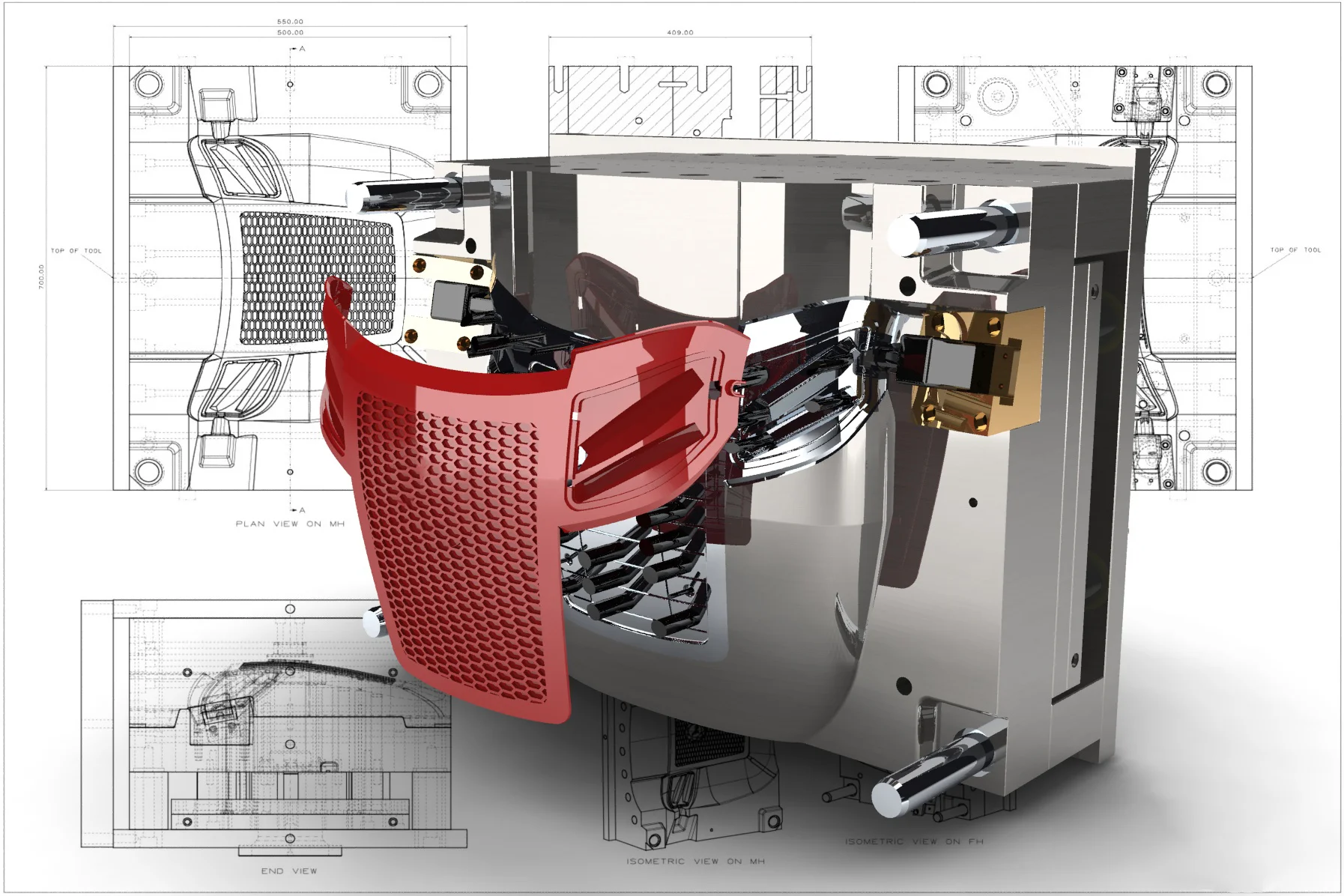

Injection Mould Tooling

We manufacture compression and injection mould tooling, designed to match your quantities and timescales. Manufacturing in UK and in China, in high specification aluminium alloys and a range of steels, we configure the tooling to your requirements. Hence whether you need 10 parts in an engineering polymer or a batch of 100,000, we can supply tooling and parts for your application.

Development Tooling

There are times when product development can only take place on components produced in production intent materials. Manufacturing tooling at this early stage in a development programme is high risk as the design is immature and change will almost certainly be required.

We have the experience and expertise to create development tooling quickly and factor in potential changes so that they can be realised with the minimum of delay. This facilitates either the creation of several options or the iterative tuning of a part to achieve your design goal.

We are injection moulding specialists so if you would like to discuss your development programme, please get in touch.

Rapid Tooling Or Prototyping

This class of tooling is driven by the need for speed! We are used to plastic prototypes in circa five days from Stereolithography and Laser Sintering; therefore this class of tooling is all about getting injection moulded prototypes, in production materials, as fast as possible.

This is achieved through standardisation where possible and the use of lose inserts if applicable to resolve undercut features. We regularly use prototype tooling to produce injection moulded parts in quantities ranging from sub one hundred to low thousands.

We are injection moulding specialists so if you think this would help your development programme, please get in touch.

Bridge Tooling

The initial application for bridge tooling was to ‘bridge’ the gap between prototype and production, however today we commonly use this as a low volume production tool with great success.

Addressing the need for a cosmetic finish, injection moulded materials and a short leadtime, bridge tooling can be invoked due to the leadtime associated with the production tooling, programme slippage, market research, or often as a low volume production tool.

Manufactured from a large range of aluminiums and steels, the life of these tools can run into tens of thousands of parts. An option we know will effectively deliver many of the advantages of production tooling without the long leadtime!

We are injection moulding specialists so if we could help your development programme through bridge tooling, please get in touch.

Production Tooling

Our production tooling is manufactured in a range of tool steels to suit the tool life requirement, and sourced from the UK and the Far East depending on time, logistics and client preference.

Tooling can be manufactured and then moulded in a wide range of engineering materials including ABS, PC, ABS/PC, PA, PAGF, Ultem, and PVC to name a few.

Production call off can be scheduled and shipped as required worldwide. Alternatively Protobroker can arrange for these tools to be shipped after trialing, for the client to mould in house or at their nominated supplier.

We are injection moulding specialists so if we could help with your development programme, please get in touch.